Steel is the most widely used metal in the industry. There are THOUSANDS types of steels depending on the requirements of its application. Steel is typically a composition of iron and carbon and other alloying elements that confer specific mechanical and physical properties. Families classifying steel are: LOW CARBON STEEL (MILD STEEL), MEDIUM to HIGH CARBON STEEL; LOW, MEDIUM and HIGH ALLOYED STEEL (with nickel, chromium, molybdenum, manganese, and others). The higher the carbon content in the steel, the higher its mechanical strength, hardness, but also its brittleness and difficulty to weld with normal mild steel electrodes. Also the higher the amount of alloying elements, the higher the difficulty to weld.

In the field of production of new assemblies, welding is accomplished using different specific electrodes or wires depending on the specific chemical composition of the steel to be welded, using specific welding procedures manual or automated that assume in some cases pre-heating and/or post-heating steps. The metals are new, clean, well aligned and welders are qualified for specific procedures and the job is repetitive.

In maintenance, reality becomes so complicated because the machinery or equipment to be repaired is made of different types of steels, whose chemical composition is often unknown, dirty, greasy, painted or galvanized. The maintenance staff should keep in stock dozens of types of electrodes, with the great risk of not knowing which one to use and make welds that could break after a short time, causing dangerous damages and downtimes, thus a considerable waste of time and money loss. They often have to weld directly on the machine, not in optimal conditions, without adequate equipment, often with parts not well aligned.

For this reasons MALLOY has developed a range of technologically advanced products that face these difficult conditions and allow to safely repair any steels: MALLOY 303AR, MALLOY 304.

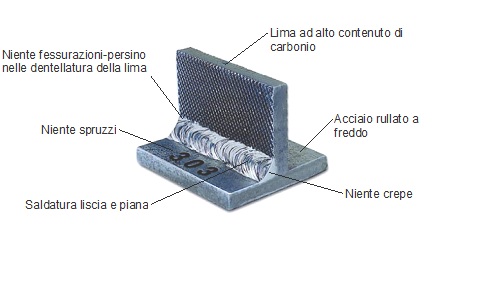

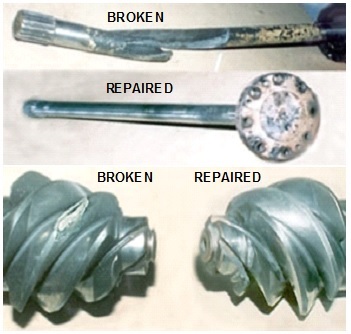

MALLOY 303 AR is a special electrode that allows to repair welding of all steels, including dissimilar combinations between them. It has a high mechanical strength, high elongation to prevent cracks and breaks, it is shock, corrosion and heat resistant, and can weld in every positions. It is therefore an universal electrode that all maintenance department should adopt as the RIGHT SOLUTION FOR ALL STEEL REPAIR, since it eliminates doubts and mistakes in choosing the right electrode when you don’t know the type of steel to be repaired, and because it reduces the electrodes inventory as one electrode can do the jobs of many others.

MALLOY 304 is a universal electrode for repair works on mild steels or low alloyed steels. It is extremely easy to use in all positions. Welds with contact (DRAG) type transfer even in presence of dirt, grease, paint, rust and wet. It can bent to easily weld IN SITU in restricted areas.

With these MALLOY special electrodes you can easily and safely repair any piece of steel, without having to dismantle and discard it or sending to a costly external workshops for repairing.

This means SAVE TIME and MONEY!

ELECTRODES FOR STEEL

MALLOY has developed a range of technologically advanced products to face all the difficult conditions of maintenance and allow safely any steel repair:

- MALLOY 303AR

- MALLOY 304

- MALLOY 394